Cnc Drill Line Kinnmaske V-line

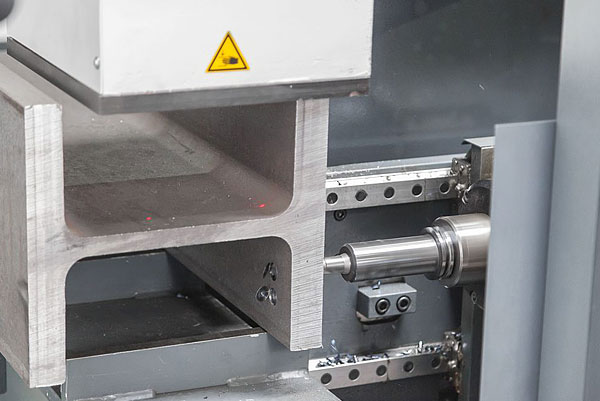

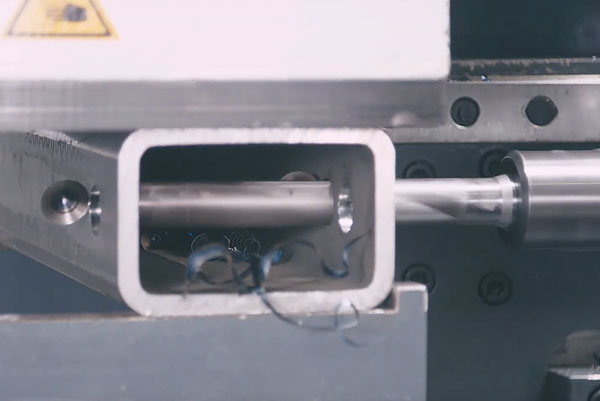

Z-Reader Probe-The Z-Reader Probe is a device that maps the location of the surface. It can be programmed or manually controlled. It can be disabled while cutting, and it can be pulled out of harm's reach. It can be activated to verify the surface at each pierce prior to cutting, or to drive surface mapping for the entire part before cutting begins. It is used to initialize or zero the device to the desired surface and then tracks or accumulates the difference between that zeroing effort.

At GSS Machinery we are committed to providing you as many options as possible with regard to drilling with your CNC Drill Line or any other CNC Beam Drill Line.